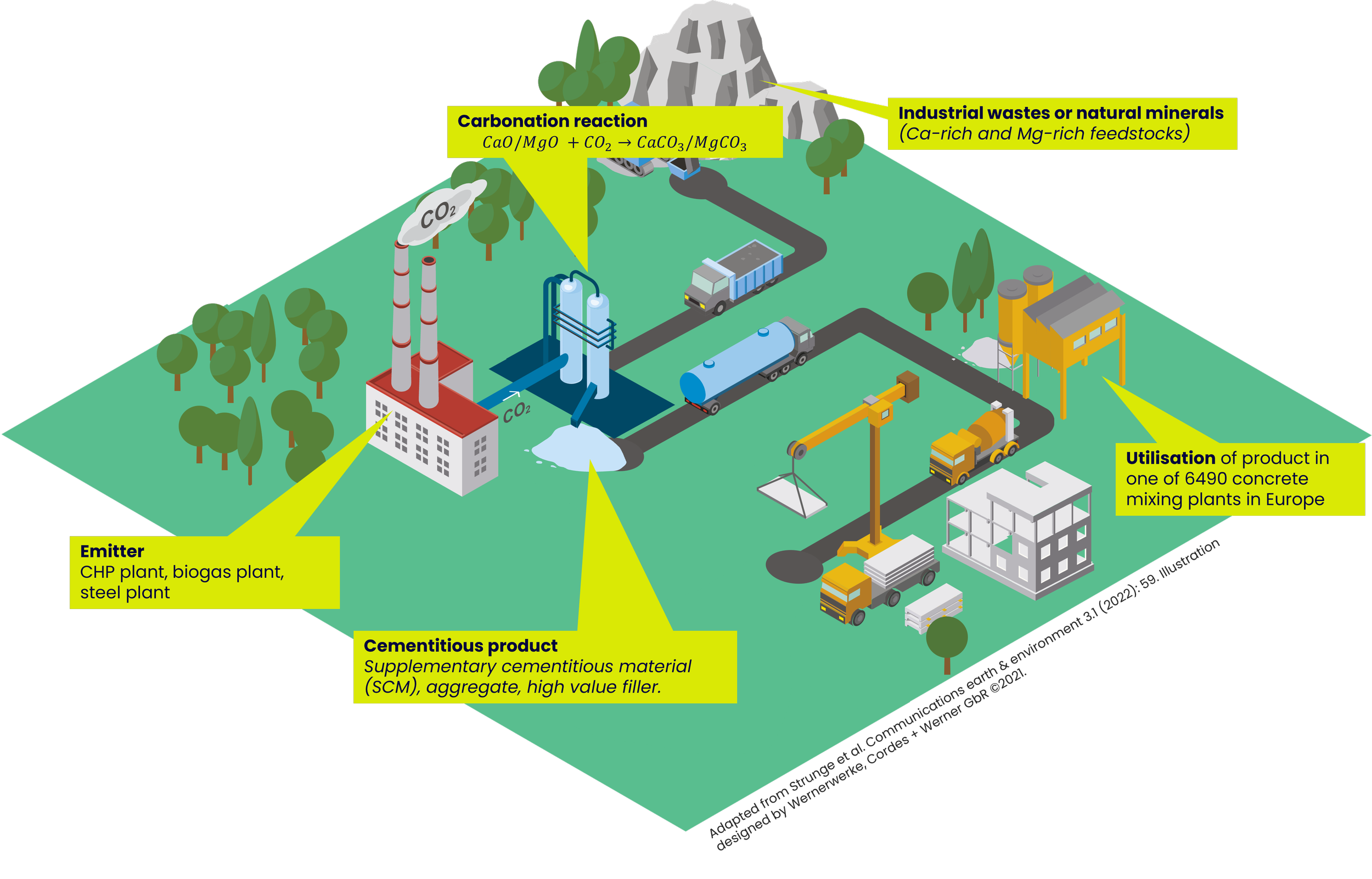

Our decentralized approach to storing CO2

Our decentralized approach to CO2 storage envisions reacting CO2 emissions where they occur with locally available industrial wastes. The technology can be deployed directly next to emission sources such as CHP or biogas plants.

Our Scales

Our demonstrator has been running since January 2025 and operates semi-continuously, using a proprietary reactor designed to enhance CO2 mineralization efficiency.

Capacity: Stores several kilograms of CO2 per hour, translating to tens of tonnes of CO2 stored per year*.

Kalz Kilo

We are currently constructing a scale-up demonstrator featuring our proprietary vibrational vortex reactor designed for continuous operation, scheduled to be operational by early 2026.

Capacity: Stores hundreds of kilograms of CO2 per hour, translating to a few thousand tonnes of CO2 stored per year*.

*If operated continuously.

Kalz Mega

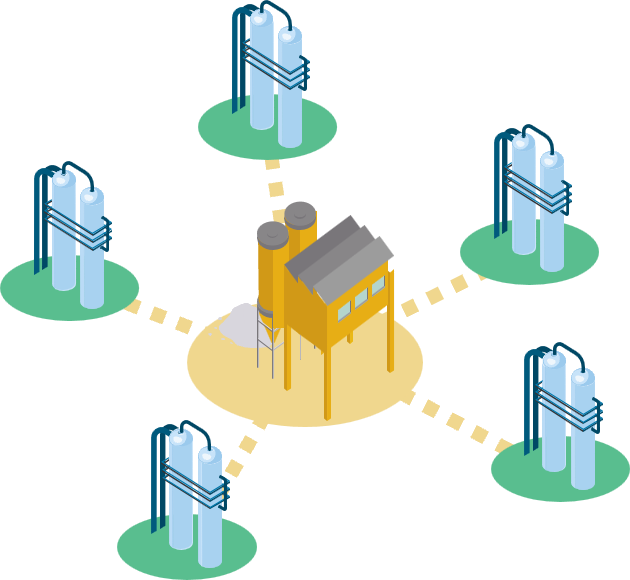

Our long-term vision is to establish mineralization hubs that connect local resources with multiple CO2 emitters, with each hub designed to permanently store thousands of tonnes of CO2.

Capacity: Tens of thousand of tonnes of CO2 stored per year*.

Mineralization Hubs